In a world increasingly focused on environmental sustainability, the garment manufacturing industry has come under scrutiny for its impact on the planet. From water usage to waste generation, traditional practices have often been detrimental to the environment. However, there is a growing awareness within the industry about the need for change. This blog explores sustainable practices in garment manufacturing and provides insights into how the industry can go green.

-

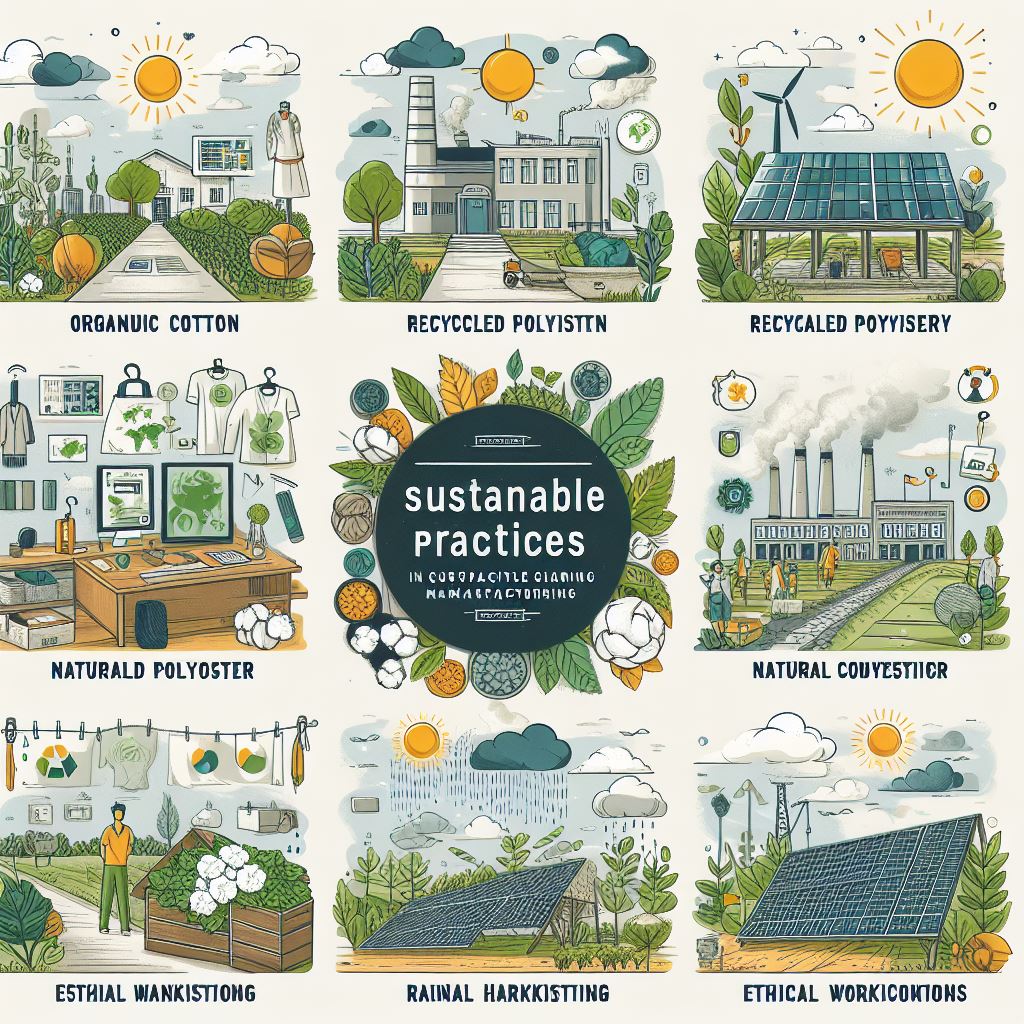

Material Selection: The first step towards sustainable garment manufacturing begins with the selection of eco-friendly materials. Opting for organic cotton, hemp, bamboo, and recycled fabrics significantly reduces the environmental footprint of the production process. These materials often require less water and fewer pesticides, contributing to a healthier planet.

-

Water Conservation: The textile industry is notorious for its high water consumption. Adopting water-efficient practices is crucial for sustainable garment manufacturing. Technologies like water recycling and closed-loop systems can significantly reduce water usage. Implementing water management strategies, such as rainwater harvesting, further minimizes the industry's impact on water resources.

-

Energy Efficiency: Embracing energy-efficient technologies is a key aspect of going green in garment manufacturing. Investing in renewable energy sources, such as solar and wind power, can substantially reduce the carbon footprint of factories. Implementing energy-saving measures, like LED lighting and optimized machinery, also contributes to a more sustainable production process.

-

Waste Reduction and Recycling: Waste generation is a significant issue in the fashion industry. Adopting a zero-waste approach involves rethinking production processes to minimize waste. Manufacturers can explore innovative recycling methods for both pre-consumer and post-consumer waste. Designing garments with recyclability in mind and promoting circular fashion can further contribute to waste reduction.

-

Supply Chain Transparency: Transparency is crucial for sustainable garment manufacturing. Brands should collaborate with suppliers who adhere to ethical and environmentally responsible practices. A transparent supply chain enables consumers to make informed choices and encourages responsible manufacturing practices from the source to the final product.

-

Local and Ethical Production: Choosing local production over outsourcing not only reduces the carbon footprint associated with transportation but also supports local economies. Ethical production practices, such as fair wages and safe working conditions, are integral to sustainable garment manufacturing. Brands that prioritize ethical standards foster a positive impact on both people and the planet.

-

Innovation and Technology: Embracing innovation and technology is essential for the evolution of sustainable garment manufacturing. Advancements in 3D printing, digital pattern-making, and artificial intelligence can optimize production processes, reduce waste, and improve overall efficiency.

Conclusion: As consumer awareness of environmental issues grows, the garment manufacturing industry must adapt to more sustainable practices. By prioritizing material selection, water conservation, energy efficiency, waste reduction, supply chain transparency, and ethical production, the industry can make significant strides toward going green. It is a collective effort involving manufacturers, brands, and buyers to drive positive change and create a more sustainable future for the fashion industry.